![]()

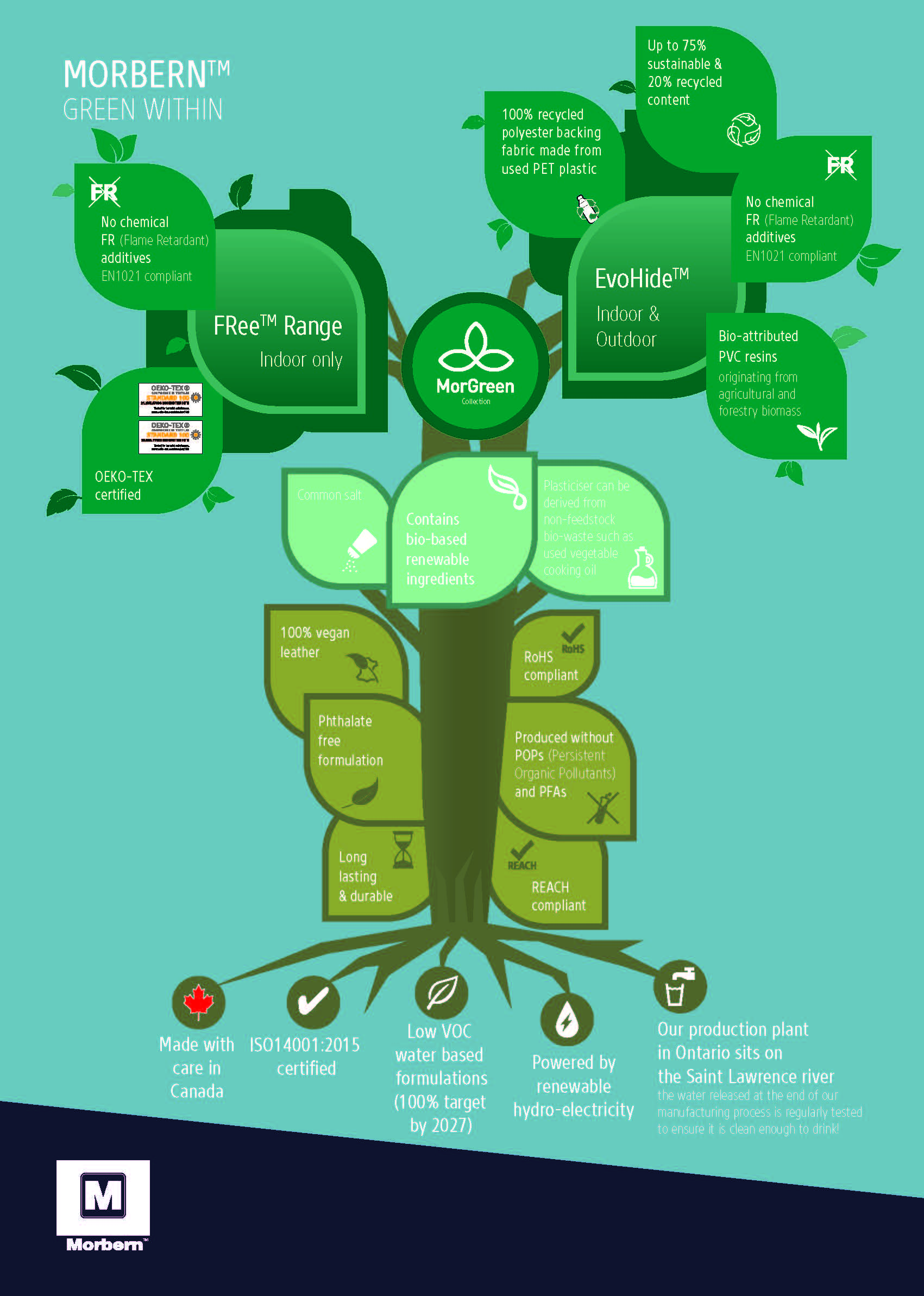

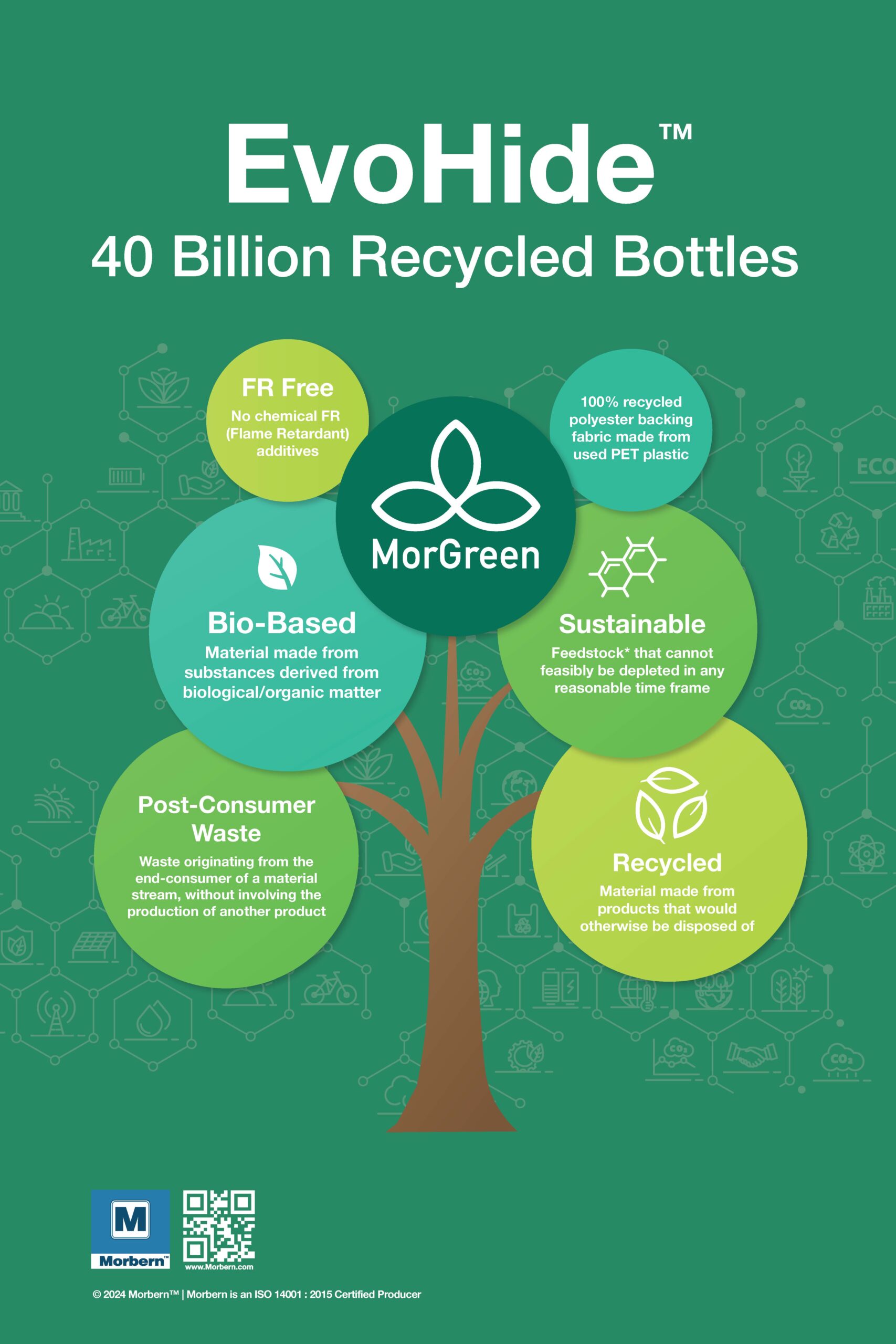

MorGreen is the story of Morbern’s journey toward sustainability and the products that exemplify it.

The Green Story

Policy

Morbern’s Environmental Management System outlines policies and procedures that govern the environmental impacts of our activities, products, and services. From rules on waste handling to research ventures into renewable products, Morbern continually works to be sustainable and responsible to leave as little environmental impact as possible.

In addition to our own policy, Morbern manages all known compliance obligations, rules and regulations according to ISO 14001:2015, an international management system standard that outlines how organizations can enhance environmental performance.

What does that mean? We decrease our environmental impact, and prevent degradation of the environment and wildlife by:

- Improving waste management

- Exploring new materials and processes with reduced environmental footprint

- Decreasing reliance on non-renewable energy and fossil fuels

- Continually educating ourselves to prevent environmental pollution, preserve natural resources, and improve the EMS

Morbern’s Green Report is available here.

Read on to learn how Morbern fulfills these promises, and creates positive outcomes for our community.

Accomplishments

-

- Sustainable/Renewable energy

-

- 99% of the energy (hydroelectric power) used by the Morbern production plant is renewable.

-

- Air quality

-

- A new coater reduces fume emissions by 50 percent, improving the community air quality.

- Low volatile organic compounds (VOC) water-based top coat finishes have now replaced most solvent formulations

- Morbern created one of the first flame-retardant-free vinyls

- All non-automotive vinyls are formulated phthalate free.

-

- Water usage

-

- We ensure the water flowing out at the end of the manufacturing process is clean enough to drink.

- Closed-loop cooling circuits installed in 2016 reduced our water consumption by more than 75%.

-

- Use of Recyclable materials

-

- The roll cores of FR free product range are made from recycled cardboard.

-

- Reduction of land fill / Use of Compostable materials

- Our dedicated second-quality team redirects material to other markets and applications so that it is kept out of landfill sites.

- The ink room’s new coater operates more efficiently than previous equipment, reducing waste disposal by 20 percent.

- Sustainable/Renewable energy

Certifications

Oeko-Tex Certification

Oeko-Tex® is a European toxicity test that evaluates textiles for the presence of a broad array of harmful substances that may cause potential health impacts through direct skin contact. Four classes of certification are granted to textiles that meet or fall below specified limits for a broad array of chemicals.

- Class I textiles are the least harmful and are approved for children up to two years old under any exposure condition.

- Class II textiles are approved for textile applications in which adult skin is exposed to large surface areas of the textile.

- Class III textiles are approved textile applications in which adult skin is exposed to small surface areas.

- Class IV textiles are approved for furnishings.

ISO 14001 registration

ISO (International Organization for Standardization) is a Geneva-based non-governmental organization established in 1947. Representing over 150 countries worldwide, ISO’s objective is to promote standardized practices in the international trade of goods and services. The ISO 14001 standard focuses on environmental management.

To obtain registration, all corporate practices are carefully evaluated and measured for environmental impact. An environmental policy is defined, including concrete goals to reduce the effects identified. This environmental policy includes a commitment to compliance with environmental laws and company policies, continual improvement and prevention of pollution.

An environmental management system is created to ensure that environmental policy is implemented. An independent ISO consultant is retained to continually monitor and measure progress, and to verify that ISO standards are observed. ISO 14001 processes are audited on an annual basis and registered companies must demonstrate continual reduction of their environmental impact.